First-class design concept, Strong R&D capability

SCROLL THE MOUSE

According to different conditions of use, it is very important to choose a reasonable material mix. There are currently four commonly used material mix schemes.

R: Rubber impeller + rubber sheath + rubber shield (medium fine particles, medium and low head).

M: Metal impeller + metal sheath + metal shield (high temperature, containing mineral oil).

MR: Metal impeller + rubber sheath + rubber shield (medium and coarse particles, high-lift delivery, semi-self-grinding and discharging).

MMR: metal impeller + metal front guard + rubber sheath (medium coarse particle, high head, used when pump may be stuck).

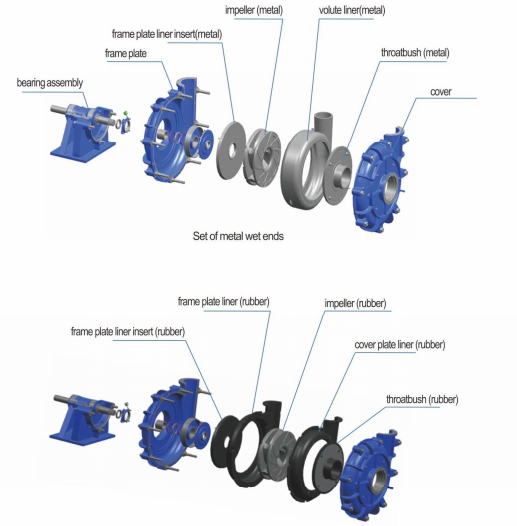

According to different applications, different materials for pump wet ends are important. Four commonly used materials collocation schemes are as follows:

R:Rubber impeller + Rubber cover plate liner + Rubber frame plate liner and insert ((medium fine particles, medium and low head).

M:Metal impeller + Metal volute liner + Metal frame plate liner insert + Metal thoathbush (high temperature, containing mineral oil).

MR:Metal impeller + Rubber cover plate liner + Rubber frame plate liner(medium and coarse particles, high-lift delivery, semi-self-grinding and discharging).

MMR:Metal impeller + Metal thoathbush + Rubber cover plate liner and frame plate liner (Medium coarse grain, high head conveying,To prevent the pump from being stuck).

Product introduction

Product advantages

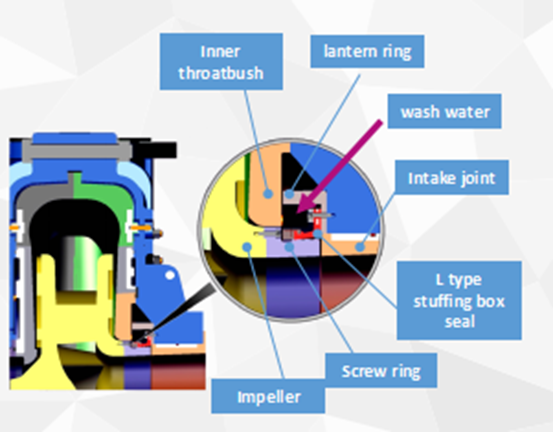

Adopt innovative gland seal design (patent protection)