First-class design concept, Strong R&D capability

SCROLL THE MOUSE

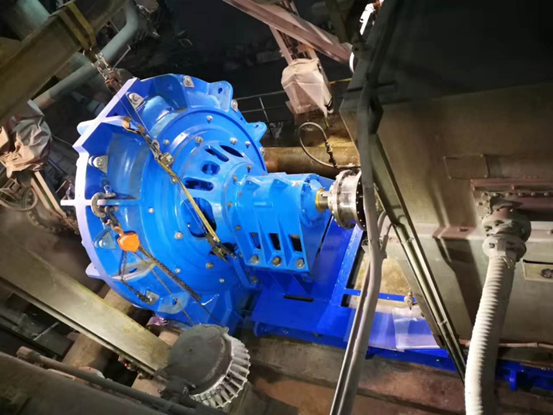

The NZJM series slurry pump is a new generation of heavy-duty slurry pump, a heavy-duty slurry pump designed specifically for conveying the discharge from the mill to the cyclone. The structure adopts a horizontal double shell, and the inner shell is also a vulnerable part for over-current, which needs to be replaced periodically. According to the difference in working conditions, high-chromium metal or rubber can be used, but the impeller is generally made of high-chromium metal. Due to the discharging and conveying of the mill, the structure design adopts the overweight wear design. The hydraulic design uses ANSYS to calculate the solid-liquid coupling to predict the wear. At the same time, the large-diameter impeller design is adopted to reduce the working speed of the pump. and improve anti-wear performance.

Product Introduction

1, Overview

Engineered for dense slurry duties, NZJM mill circuit pump is specially for conveying slurry from SAG or ball mill discharge to cyclone. Using metal impeller and rubber liners or pure metal wet parts, NZJM pump is the best solution to Improve anti-wear performance and extend product life in the highly abrasive and corrosive condition. The calculation of Hydraulics by ANSYS can greatly predict the wear and the design of big impeller can lower pump speed and increase the part life.

2, Features

2.1 The gap between throatbush and impeller can be continually adjusted to keep a small size after a certain amount of wear,which can reduce the return flow and the entry of large particles, and finally improve the wet parts life.

2.2 High-chrome or rubber liner can be selected for different applications.

2.3 Both pumps of cockwise and counterclockwise rotations can be supplied to facilitate outlet direction on site.

2.4 Horizontal and double-casing design makes the installation on site more convenient.

2.5 Grease lubrication of bearing assembly is easy to maintain.

2.6 Wet parts can be changed by Full--In-One design on large size pumps.

2.7 Outlet of pump can be adjusted to eight directions to suit the site condition.

3, Applications

3.1 Mill cyclone feed application in non-ferrous, ferrous and other metal mines;

3.2 Recommend head of single stage pump is 60m and max head is no more than 70m.

3.3 Density of slurry is less than 65%

3.4 Max. Applicable temperature of rubber wet parts is no more than 70℃

3.5 Max. Pressure for the pump is 900kpa

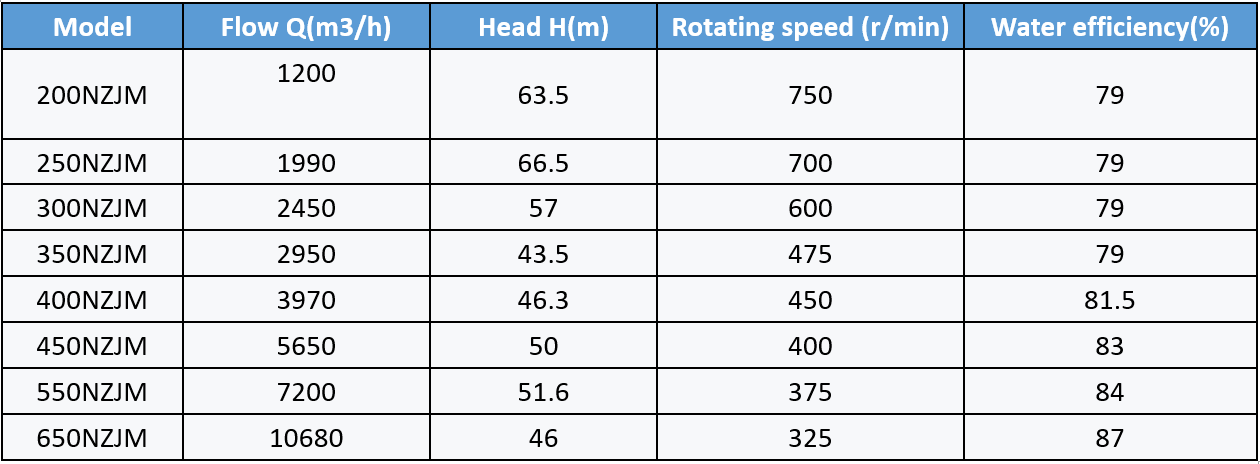

4, Specifications

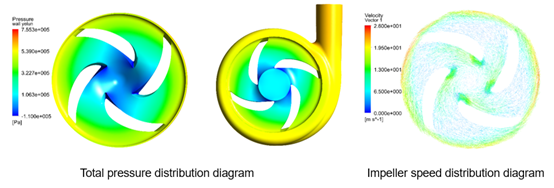

4.1 Model building and meshing

1. UG three-dimensional modeling, extracting and calculating water bodies;

2. The grid adopts hexahedral unstructured grid and is divided by ICEM software.

4.2 Model building and meshing

1, Calculation model

2, ANSYS-FLUENT calculation model software analysis;

MRF under multiple coordinates is used to solve the problem, and the turbulence model uses RNG;

3, The momentum equation and the continuity equation are solved simultaneously using the SIMPLEC algorithm.

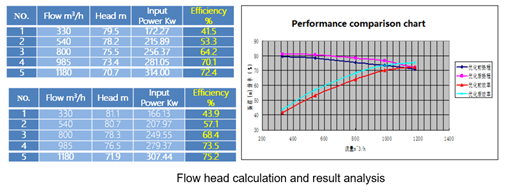

4.3 Estimation of head efficiency

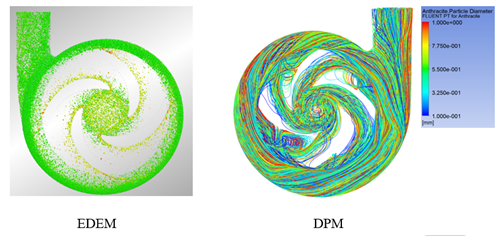

4.4 EDEM particle trajectory/FLUENT discrete phase DPM

6,Cases

550NZJM pump in an iron ore mine of Peru

650NZJM pump in an iron ore mine of Peru

450 NZJM pump in SCM copper mine of Congo

350NZJM pump in Kamoa copper mine of Congo