SCROLL THE MOUSE

Foto of Naipu's second plant construction

Foto of Naipu's second plant construction

Construction of the new materials expansion project (The Second Plant of Naipu Mining Machinery), an investment by Naipu Mining Machinery, is progressing smoothly. The first plant was completed and put into operation in 2021, and just two years later, construction on the second plant has begun, demonstrating the company's strong growth momentum.

In fact, the company has seen explosive order growth in the past two years. Building on a 50% increase in contract signings in 2022, the growth rate reached 63% in 2023. Construction of the Second Plant expansion project will more effectively meet the company's growing order demands, laying a solid foundation for further development and expansion.

The mining machinery industry plays a pivotal role in the national economy, making significant contributions to economic development. Considering both the current market development status of China's mining machinery industry and the global industrial landscape, the Chinese mining machinery sector is at a historic juncture. The next 5-10 years will be a crucial period for Chinese mining machinery companies to fully or deeply integrate into the global market and achieve shared development, with a promising outlook for the industry. It is projected that by the end of the 14th Five-Year Plan period, the sales volume of China's mining machinery industry will reach 20 trillion yuan, and exports will exceed 50 billion US dollars.

Currently, the demand for large-scale mining machinery is increasing. This is primarily evident in the areas of mineral processing ball mills and flotation machines, where the capacity of ball mills has increased 5 to 8 times in the last decade, and the capacity of autogenous mills has increased 15 to 20 times. Looking at all stages of the mineral processing procedure, there will be a greater emphasis on automation. Design principles that prioritize low energy consumption and reduced weight will be adopted, reducing energy use in production through energy-saving measures.

After nearly two decades of development, Naipu Mining Machinery, leveraging years of accumulated production experience and patented technologies from research and development in mining equipment and rubber parts manufacturing, has overcome technical bottlenecks in various production stages, achieving upgrades in production processes and the industrialization of its patented technologies. Simultaneously, with the recent recovery of domestic and international mining markets, the market demand for mining equipment and wear-resistant parts has steadily increased, exceeding the current production capacity of the company's existing workshops. To further expand its market share, Naipu proposes a Second Plant manufacturing expansion project.

Bird's eye view of the Second Plant of Naipu Mining Machinery

Bird's eye view of the Second Plant of Naipu Mining Machinery

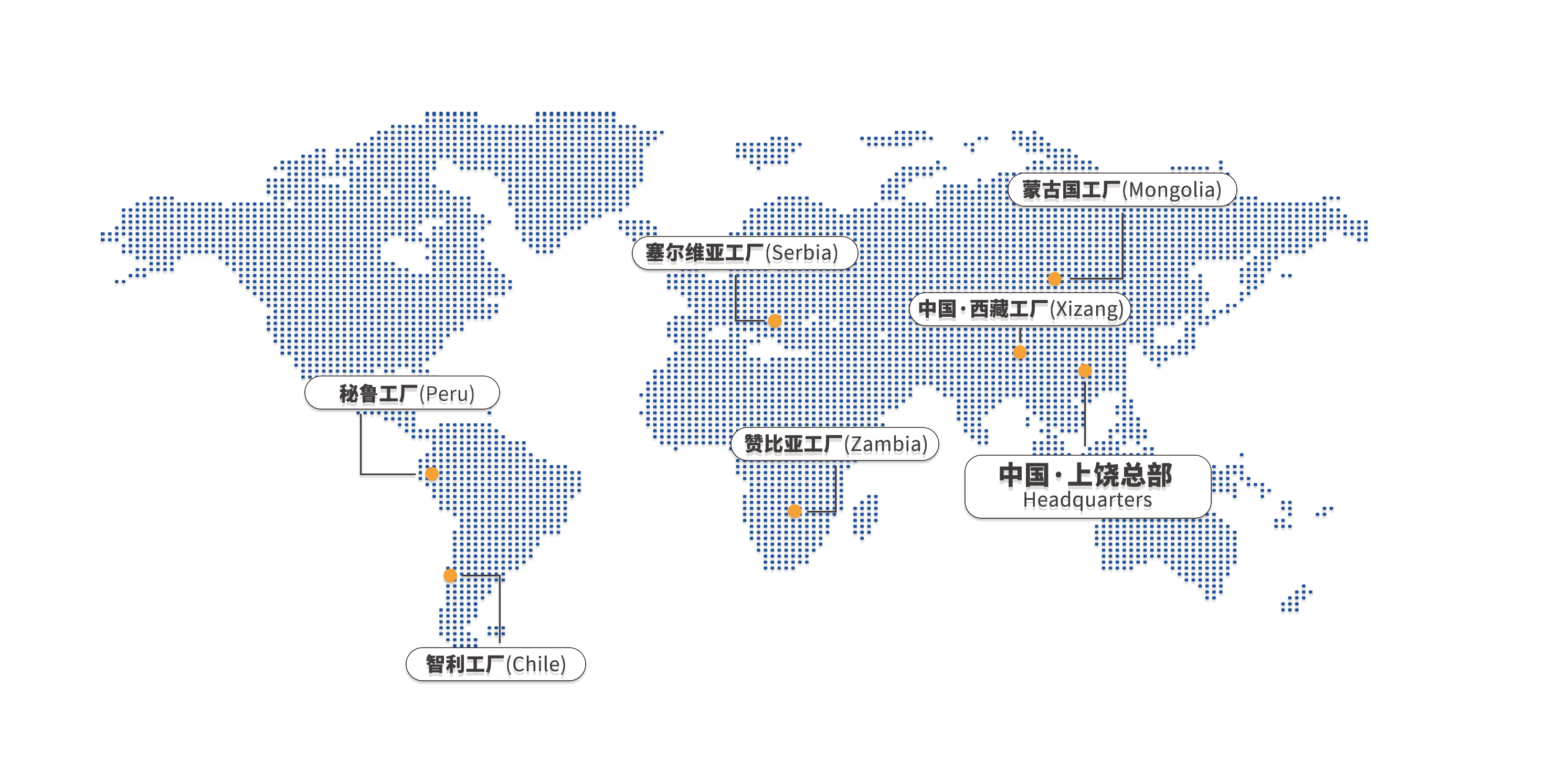

Naipu Mining Machinery boasts a comprehensive global sales network, with subsidiaries in Mongolia, Australia, Peru, Mexico, Chile, Ecuador, Singapore, Zambia, and Serbia, as well as offices in Laos and the Philippines. Targeting industry trends, the company adheres to a product development path emphasizing "high technology and high quality," achieving success through superior quality. Numerous large-scale domestic and international mining enterprises are clients, including Zijin Mining, CITIC Heavy Industries, Jiangtong Group, Luoyang Molybdenum Co., Ltd., Taiyuan Iron & Steel (Group) Co., Ltd., Western Mining, Erdenet Mining Corporation (Mongolia), Oyu Tolgoi LLC (Mongolia), ME, and KSO (Laos), among others.

For many years, Naipu Mining Machinery has adhered to independent brand building. To cultivate and develop its strength and reputation, while producing high-quality, high-tech, and high-value-added products, it also maintains a professional technical and after-sales service team, providing long-term service to major domestic and international mining and corporate clients. The company emphasizes strengthening after-sales service and promotion, and consistently researches market entry, market dominance, and the comprehensive implementation of a brand-name strategy as long-term strategic issues. Quality management and the pursuit of becoming a world-renowned brand are consistently integrated into all aspects of its production and business operations.

To address the rapid growth in orders and the increasing demand for production capacity, Naipu Mining Machinery has added equipment to its headquarters factory to boost output. Simultaneously, the Zambia production base is scheduled to commence operation in the second half of 2024, bringing a significant increase in capacity. Furthermore, construction is underway at the company's Chilean base. These measures demonstrate Naipu Mining Machinery's proactive expansion of its production capacity to meet market demand, resulting in a global strategic layout with production and service centers in Asia, Africa, Europe, and South America.

Naipu Mining Machinery's Global Market Presence

Naipu Mining Machinery's Global Market Presence